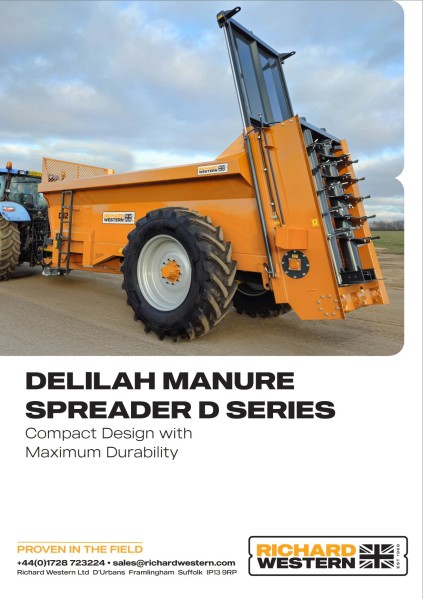

Delilah D12 Vertical Back Manure Spreader

Delilah D12

Heaped Capacity: 15.2 m³

About this product:

Design

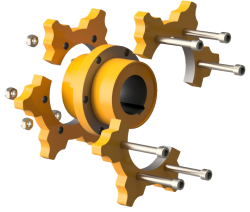

NEW BOLT-ON SPROCKETS

NEW BOLT-ON SPROCKETS

Our innovative bolt-on sprocket system revolutionizes maintenance and durability. Unlike welded sprockets, our design features a keyway connection that enhances reliability and allows for quick and easy replacement without shaft removal. This minimizes downtime, reduces labour costs, and ensures consistent performance even in demanding conditions. Built for durability, the bolt-on sprockets provide a safer and more efficient solution for long-term operations.

SUPERIOR SHREDDING PERFORMANCE

SUPERIOR SHREDDING PERFORMANCE

The Vertical D Rotor System sets a new benchmark in shredding and spreading performance. Featuring robust, overlapping 800mm diameter rotors, this system is engineered for efficiency, pulling material effortlessly from the load face to reduce unloading times significantly. The interlinking rotors work seamlessly to shred and pulverize material, ensuring an even, lump-free spread, making it particularly well-suited for grassland and minimum-tillage applications.

Designed with a focus on reliability and durability, the Vertical D Rotor System delivers consistent performance in even the most demanding conditions. Whether spreading well-rotted farmyard manure (FYM), fresh box manure, compost, green waste, poultry litter, or lime, this system offers exceptional material handling and distribution. Its ability to maintain uniformity and precision ensures that operators can trust it for a wide range of spreading tasks, contributing to optimal field application and soil management.

Overview

The new Delilah D series of vertical beater manure spreaders provide simpler alternatives to the Delilah DV models. Retaining the Delilah beater format of five complete spiral flight sections with six tips per section, the D series (D10/D12/D15, with corresponding m3 capacities) feature a reduced body width of 1,500mm, decreasing overall width from 3,000 to 2,800mm. In combination with greater use of high-strength materials, this has cut overall weight by 10%. The rotor diameter has been reduced from 890mm to 800mm without detriment to shredding performance or overlapping. The 200mm rotor tubes minimise vibration and allow a large rubber-cushioned drive zone while providing a large weld area for the five 10mm heat-treated boron spiral flights. There are two types of rotor tips, both made from heat-treated boron and arranged in a staggered formation to produce a constant rotor load and uniform distribution of shredded material.

D series spreaders feature floor sprockets with six rather than seven teeth, reducing the torque required to drive the floor. The 65mm floor shaft is connected to the floor drive gearbox with a 30-spline shaft, a design unique to Richard Western that provides a greater engagement area than the standard keyway shaft. While the floor sprocket uses the key to the shaft, the sprockets are bolted to the hub, meaning shaft removal is not required should sprocket replacement be necessary.

Standard Features

BOLT-ON SWIVEL Ø50MM TOWING HITCH

The swivel feature allows for multidirectional movement, providing enhanced manoeuvrability when towing. This is especially valuable when navigating tight corners or uneven terrain.

The swivel feature allows for multidirectional movement, providing enhanced manoeuvrability when towing. This is especially valuable when navigating tight corners or uneven terrain.

WIDE ANGLE PTO

The PTO can remain engaged during headland turns, all thanks to the wide-angle joint. It is important to be aware that the manufacturer discourages turning with the PTO under load.

FOOR CHAINS

Hydraulically driven floor with heavy-duty 32t calibrated 16mm grade 80 chain with individual tensioning and a full-width floating floor slat gives an even spreading rate and prevents bridging.

Hydraulically driven floor with heavy-duty 32t calibrated 16mm grade 80 chain with individual tensioning and a full-width floating floor slat gives an even spreading rate and prevents bridging.

FLOOR SPROCKETS

The 6-teeth floor sprocket features a keyway connection and bolt-on design, allowing easy replacement without shaft removal. It reduces wear by up to 20% compared to 5-teeth sprockets, enhancing durability and simplifying maintenance.

The 6-teeth floor sprocket features a keyway connection and bolt-on design, allowing easy replacement without shaft removal. It reduces wear by up to 20% compared to 5-teeth sprockets, enhancing durability and simplifying maintenance.

FLOOR DRIVE GEARBOX

The RT500 Gearbox, fitted on D10 and D12 models and RT800 on D15 includes a 65mm floor shaft with a unique 30-spline design to Richard Western spreaders for superior engagement. An adjustable relief valve adds protection.

The RT500 Gearbox, fitted on D10 and D12 models and RT800 on D15 includes a 65mm floor shaft with a unique 30-spline design to Richard Western spreaders for superior engagement. An adjustable relief valve adds protection.

RUBBER CUSHION

The rubber cushion drive coupling is specially developed to reduce shock loads to the auger drive gearbox.

The rubber cushion drive coupling is specially developed to reduce shock loads to the auger drive gearbox.

ROTOR TIPS

D Series have 60 heat-treated BORON (50mmx12mm) tips fitted on a spreader, we use 2 different tip designs, twisted and straight 30 of each and arranged in a staggered formation to produce a constant rotor load and uniform distribution of shredded material.

D Series have 60 heat-treated BORON (50mmx12mm) tips fitted on a spreader, we use 2 different tip designs, twisted and straight 30 of each and arranged in a staggered formation to produce a constant rotor load and uniform distribution of shredded material.

800MM ROTORS

Our 800mm rotors, with five spiral flights of 10mm heat-treated BORON steel and a 195mm rotor tube, ensure superior shredding performance. The larger tube minimises vibration, enhancing efficiency and reliability in operation.

Optional Equipment

- Hydraulic Slurry Door

- Air Brakes

- Lift off canopy

- Rear Drawbar c/w hydraulic brakes & electrics

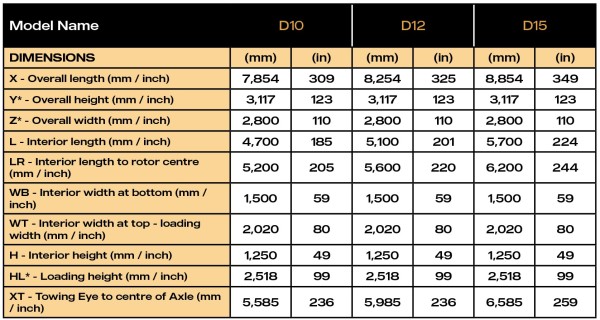

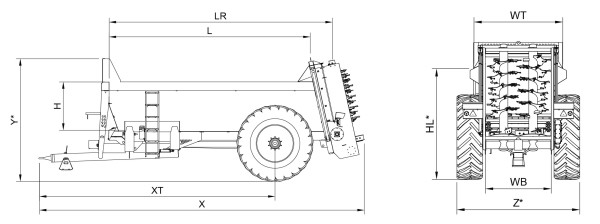

Dimensions

Find your nearest dealer

From our international network

Product Manual

Product Manual

Delilah D Series Brochure

Delilah D Series Brochure

RW Product Guide

RW Product Guide